PXP®-1000 System

Overview

Advanced Technology for Cell Separation

The PXP®-1000 System is designed to provide a fast, automated, and reproducible separation of cord blood with minimal red blood cell contamination in a closed and sterile environment.

Powerful, Efficient, and User Friendly

The PXP-1000 System is used for processing and separating buffy coat from collected units of cord blood. Buffy coat is a cell fraction of cord blood that includes most of the leukocytes, stem and progenitor cells, nucleated red cells, some plasma, some erythrocytes and most of the platelets. The separation process takes place in a commercially-available, programmable centrifuge. During high-speed centrifugation cord blood is stratified into three components: buffy coat, red blood cells (RBCs), and plasma. After stratification and during the low-speed centrifugation, RBCs are depleted into the depletion chamber and buffy coat is harvested into the harvest chamber compartment of the PXP-1000 Disposable Cartridge.

Complete System Solution

- PXP-1000 Disposable Cartridge

- PXP-1000 Control Module

- PXP-1000 Docking Station

- DataTrak Software

- Accessories

Uncompromised Results

- High CD34+ and MNC recovery (>90%)

- Consistent final volume of 20 +/- 1 mL

- Process volumes between 40-240 mL

- Enrichment of stem and progenitor cells in approximately 35 minutes

- Process up to 4 samples at a time

INDICATION: The PXP®-1000 System is a cord blood cell processing system intended for processing umbilical cord blood in combination with a specific and compatible single-use separation kit supplied by ThermoGenesis Corp.

Working with the PXP®-1000 System

Behind the Technology

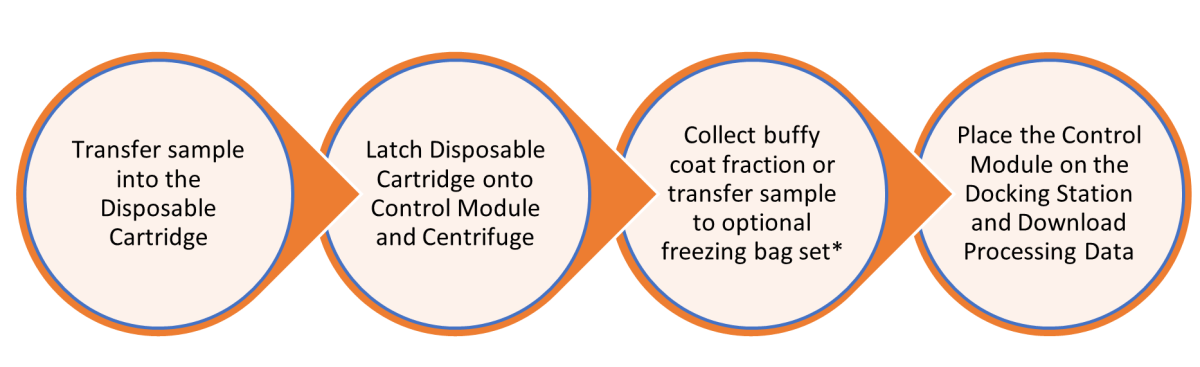

The PXP®-1000 System includes a sterile Disposable Cartridge, a battery operated Control Module, a Docking Station, and DataTrak software for cGMP purposes. During centrifugation, the electromechanical Control Module directs the Disposable Cartridge to isolate different components of blood into the three chambers. The Disposable Cartridge is filled with blood through a 150-micron clot filter, attached into the Control Module, and inserted into the centrifuge bucket.

During centrifugation at high speed for approximately 20 minutes, the blood is stratified into three layers, from bottom to top: the red blood cell (RBC) layer, the buffy coat layer, and the plasma layer. After stratification, the centrifuge automatically lowers to a much lower G force and a motorized cam in the Control Module rotates, releasing the pinch of the transfer tube. The compacted RBC fraction is released through the transfer tube into the depletion chamber of the Disposable Cartridge. Simultaneously, the buffy coat layer follows the RBC fraction down the Disposable Cartridge funnel into the narrowed section where the optical sensors detect the RBC/Buffy Coat interface. When the programmed optical transmittance values are detected, the Control Module directs the motorized cam to rotate and re-pinch the RBC transfer tubing of the Disposable Cartridge. The centrifuge accelerates to a higher G force for a short period to restratify the remaining plasma and white blood cells. Towards the end of the process, the centrifuge decelerates to a low speed where the cam motor rotates to release the pinch on the harvest transfer tubing so the buffy coat layer and some plasma is transferred to the harvest chamber.

Once the centrifuge cycle ends, the control module is docked on the Docking Station and data collected during the centrifugation process can be downloaded to a host computer using the DataTrak Software. The harvested buffy coat can be collected via a syringe or stored and cryopreserved using an optional freezing bag set*.

PXP®-1000 Work Flow

*ThermoGenesis Corp. also offers the 3D Bag Set (REF # 80105) that is compatible with the PXP-1000 System and allows for storage of concentrated buffy coat and addition of a cryoprotectant.